Lactic Acid Bacteria is a major factor to improve the life and health of consumers, providing safe and nutritious foods, is the major concern in Food Science. Toward that goal, preservation methods such as salting, drying, high/low temperature application, fermentation, and more recently, pulsed electric field, high pressure and radiation – alone or in combination – may be applied. The chosen method will depend on the type of raw materials, availability of the method, cost, effectiveness and degree of change it causes to the flavor and nutritional features of the food product.

Lactic acid bacteria Fermentation:

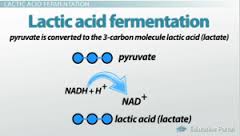

Fermentation, also called biopreservation, is a cheap, widely accessible method that meets today’s increasing consumer’s demand for minimally processed/preserved food products. Biopreservation with lactic acid bacteria (LAB) is indeed one of the oldest and highly efficient forms of non-thermal processing method. Cheese production is based on Lactic acid bacteria ability to ferment sugars, especially glucose and galactose, so to produce lactic acid and aroma substances that give typical flavors and tastes to fermented products.

Lactic acid bacteria also release antimicrobial metabolites so called bacteriocins, which are considered safe and natural preservatives, with great potential to be used on their own, or synergistically with other methods in food preservation. Lactic acid bacteria in dairy processing Milk is a highly perishable food raw material, therefore, its transformation in cheese or other form of fermented dairy product, provides an ideal vehicle to preserve its valuable nutrients , making them available throughout the year. It is known that while unprocessed milk can be stored for only a few hours at room temperatures, cheeses may reach a shelf-live up to 5 years (depending on variety).

Fermentation with Lactic acid bacteria is a cheap and effective food preservation method that can be applied even in more rural/remote places, and leads to improvement in texture, flavor and nutritional value of many food products. Lactic acid bacteria have a long and safe history of application and consumption namely in cheese processing thus being generally regarded as safe (GRAS). Increasing knowledge of Lactic acid bacteria physiology, together with new developments in processing technology, is leading to their application beyond traditional starter culture application, namely in new food safety roles and direct health applications.

Lactic acid bacteria as starter-cultures in cheese processing Cheese-making is based on application of Lactic acid bacteria in the form of defined or undefined starter cultures that are expected to cause a rapid acidification of milk through the production of lactic acid, with the consequent decrease in pH, thus affecting a number of aspects of the cheese manufacturing process and ultimately cheese composition and quality. The earliest productions of cheeses were based on the spontaneous fermentation, resulting from the development of the microflora naturally present in the raw milk and its environment. The quality of the end product was a reflex of the microbial load and spectrum of the raw material. Spontaneous fermentation was later optimized through backslopping, i.e., inoculation of the raw material with a small quantity of whey from a previously performed successful fermentation, and the resulting product characteristics depended on the best-adapted strains dominance.

Lactic acid bacteria Today:

Today, backslopping is still used to produce many artisanal raw-milk cheeses, namely those bearing the PDO (Protected Designation of Origin) status, which are considered to be an important source of Lactic acid bacteria genetic diversity, as well as being crucial from an economic and even ecologic point of view, since production of said cheeses (usually processed on a small-scale) contributes to local employment and maintains people functioning as “guardians of local environment” in regions that otherwise would be deserted.

The starter-culture applied in this, so-called, natural fermentation, is usually a poorlyknown microflora mix that although having a predominance of Lactic acid bacteria, may also contain non Lactic acid bacteria microorganisms, and its microbial diversity and load is usually variable over time. In fact, studies directed to characterize traditional cheeses show that those made from raw milk harbor a diversity of Lactic acid bacteria depending on geographical region, where a few may show particular interesting technological features that upon optimization may have industrial applications .

For example, because wild strains need to withstand the competition of other microorganisms to survive in their hostile natural environment, they often produce antimicrobials substances called bacteriocins , which are natural antibacterial proteins that can be incorporated directly into fermented foods as such (food–grade) or indirectly as starter culture . Although nisin is today the only bacteriocin that reached commercial status, approved worldwide as a natural food preservative, many other bacteriocins may soon reach similar status. Recently, our work (to be published) with Lactic acid bacteria isolates from traditional portuguese raw-milk cheeses, revealed several lactobacilli having antibacterial activity against pathogens such as Listeria monocytogenes, Staphyloccus aureus, Salmonella newport and even E.coli.

Future of Lactic acid bacteria

Future studies may allow us using these isolates or their metabolites, applied in situ or ex situ fashion, in applications where food safety is a concern. Moreover, traditional cheeses also obtain their flavor intensity also from the non-starter lactic acid bacteria (NSLAB), which are not part of the normal starter flora but develop in the product, particularly during maturation, as a secondary flora. The isolation and optimization of wild-type strains from traditional products, to be used as starter cultures in cheese processing, is indeed a highly active field of research in Food Science today.